4. Fastening and Sealing the Unit

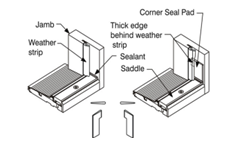

Jamb Installation:

- Apply a generous bead of sealant behind the perimeter of the jamb where it will meet the opening.

- Secure the jamb using #10 x 3/4” screws.

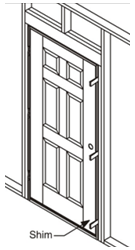

Shimming:

- Shim behind the hinge jambs, lock jambs, and head jambs to maintain a plumb and square frame.

- Place shims every 12”, 6” from the top and bottom of each jamb.

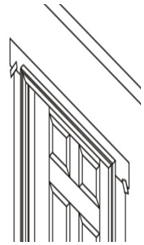

Head Jamb Sealing:

- Apply corner seal pads where the threshold meets the jamb corners for additional water protection.

Caulking the Exterior:

- Seal the perimeter of the unit where the jamb meets the sheathing.

- Apply sealant along all edges of brickmould (if present).

5. Final Adjustments and Weatherproofing

Threshold Adjustment (Inswing Doors):

- Ensure the threshold creates a tight seal with the door bottom by adjusting the set screws.

Exterior Sealing:

- Apply additional sealant at the bottom corners of the sill where it meets the jamb.

- Seal joints between exterior hardware trim and the door face to prevent water infiltration.

Insulation:

- Add insulation between the rough opening and the door frame, ensuring no compression that could bow the frame.

Cap Flashing:

-

- Install properly aligned cap flashing above the unit to divert water away from the head jamb.

6. Quality Assurance

- Inspect all caulk joints and sealants for continuity.

- Verify that the unit is square, plumb, and securely fastened.

- Confirm all exterior and sill areas are sealed to Wilson Lumber’s standards.

- Perform a final inspection to ensure all water mitigation measures are in place.

Maintenance and Recommendations

- Periodically check sealants and finishes for deterioration and reapply as needed.

- Ensure all water management systems (flashing, sill pans, sealants) remain intact.

- Swing-out doors require regular inspection of top, bottom, and side edges for finish integrity.