While there’s nothing like Southern Hospitality, the Midwest gets very close! Members of the Wilson Lumber sales team, accompanied by some of our customers, ventured up to Borden, Ind., for a tour of the Koetter Woodworking facilities and an in-depth look at their processes. The entire Koetter team showed us a wonderful, educational time!

Nestled on 83 acres in Southern Indiana, right on the Ohio River and a short drive from Louisville, Ky., Koetter Woodworking is a leading manufacturer of quality architectural wood products.

Our trip wasn’t all business though. We started off with a tour of the Louisville Slugger Museum and a bourbon blending class! It was a fun time together, and who doesn’t love baseball and bourbon?!

We were invited back to Brian Koetter’s gracious home for dinner and fellowship. I mentioned to Brian how lovely it was to gather at his home.

He said it was important to him to host us because you can’t get to know everyone at a restaurant.

It’s true, isn’t it? We were much more relaxed and at ease at his beautiful home. It allowed us to build and strengthen relationships, with our customers but also with the Koetter team. We work with this group daily, so it was great to be together in person.

Koetter Dinner

Koetter Dinner 2

Koetter Dinner 3

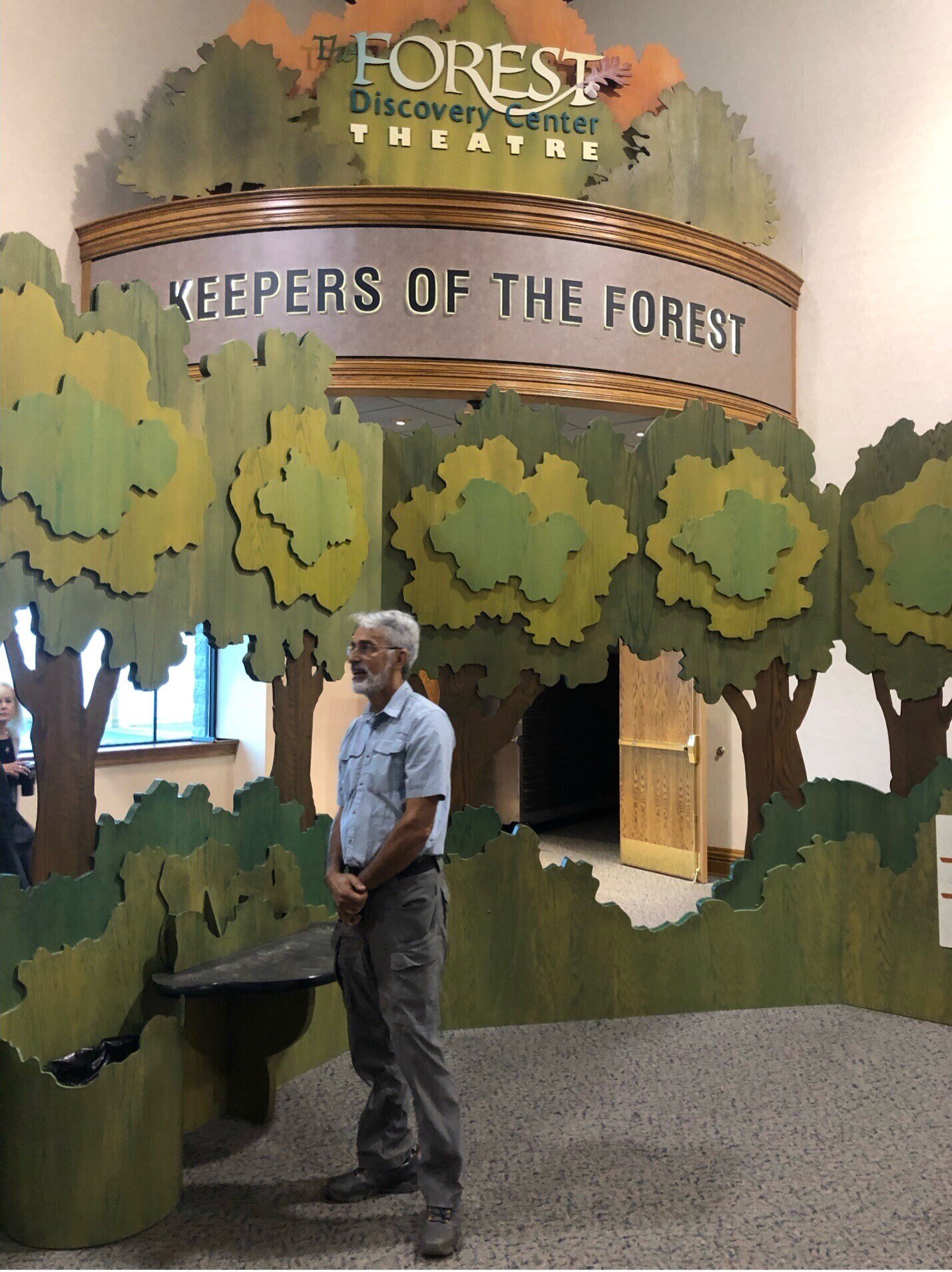

Koetter’s Forest Discovery Center was built to educate. This is where they do trainings, their in-house orientation and the occasional field trip.

The passion they have for conservation and forest management is evident the moment you step foot in the Forest Discovery Center and throughout their manufacturing facilities.

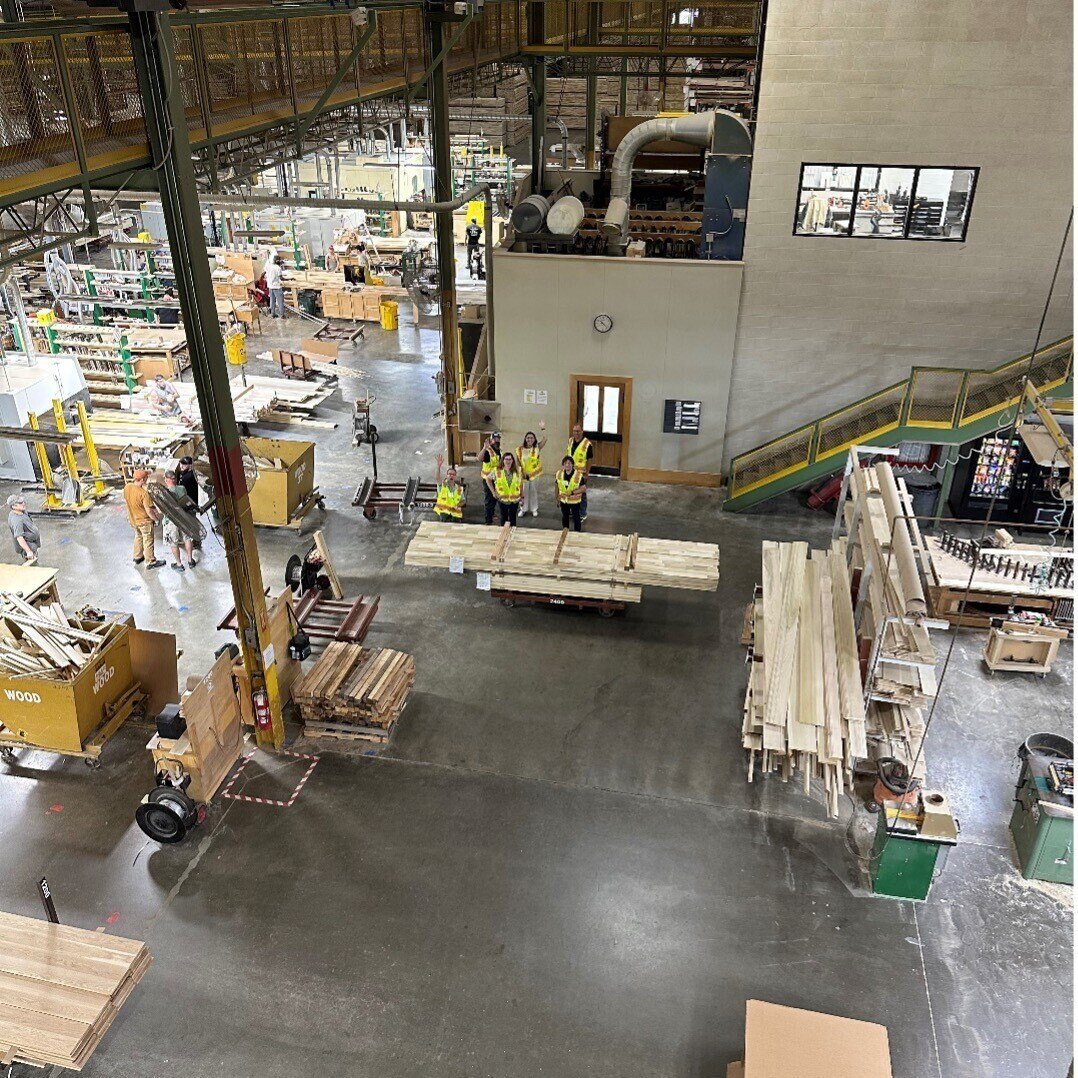

We sat down for breakfast and then headed out to tour the sprawling facilities. It’s here that Koetter kiln-dries, preps and turns wood into doors and trim. We were blown away at their dedication to sustainability, innovation and quality.

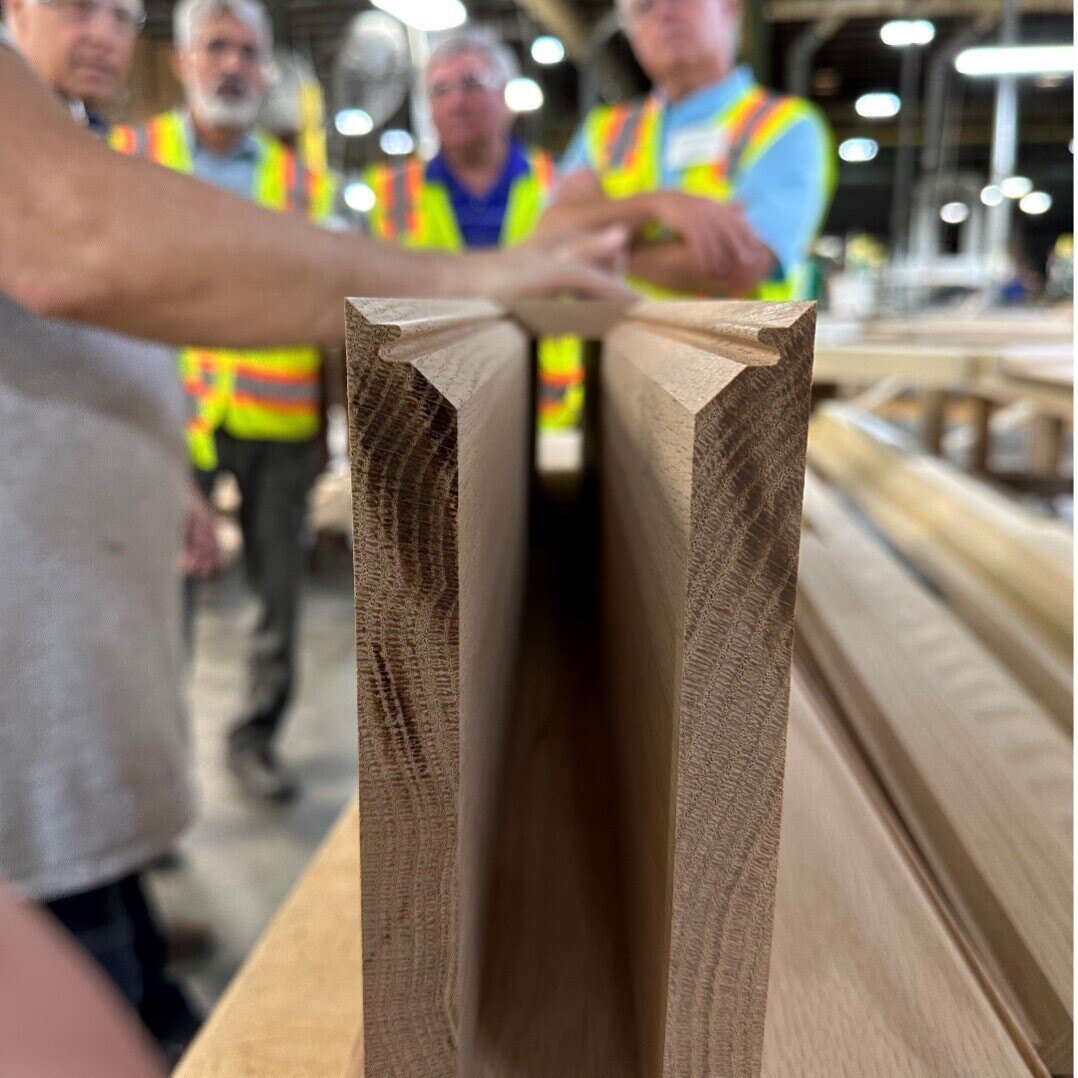

Personally, my favorite stop during our tour was visiting Reuben in the knife room. He and his team cut all the templates and knives needed to mould trim! Each knife spins in a CNC router to mold the trims. Reuben shared about their processes and the way they keep track of every knife. The attention to detail and care blew me away.

We were all excited to learn about Koetter’s Torrefied Poplar and Red Oak. Torrefaction is a process in which kiln-dried wood is super-heated to 400 degrees in the absence of oxygen, which prevents combustion. It changes the molecular structure, reducing the moisture content to 0%. It’s then conditioned by adding moisture back in through steam injection. This creates a special species that is suitable for exterior applications, increased dimensional stability, rot, mold and insect resistant! It also gives the wood an enriched grain and warm hue.

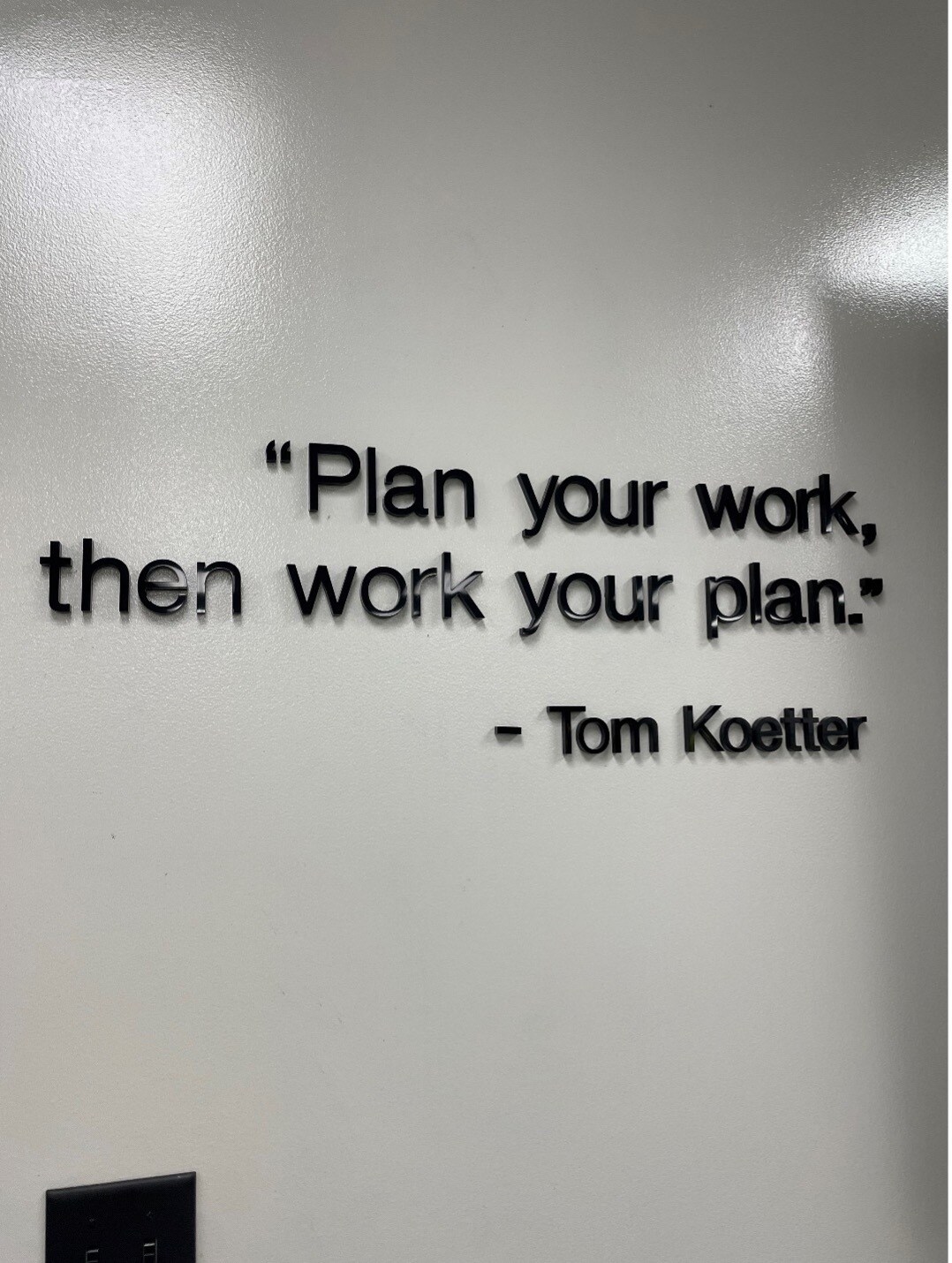

Koetter has many similarities to Wilson Lumber. Both businesses are family-owned for more than half a century, and both are dedicated to the customer. At Koetter, one of their goals is listening to the “voice of the customer." This was evident in our two days with them. We are grateful for our continued partnership with Koetter Woodworking and look forward to future visits.

Thank you, Brian, Sarah, Randy, Jerry, Eric, Carol, Jamey, Clay, Kayla and everyone at Koetter for hosting Wilson Lumber and our customers!

Contact Us

Interested in joining us on a vendor facility tour? Let us know! We are always planning a variety of tours and trainings.